Climate protection, reduction of greenhouse emissions, improving recyclability of plastics and saving of fossil resources are key elements for a more sustainable future

Design of new composite materials (bio-based and fossil-based) with higher recyclability rates. These materials should offer excellent properties for a wide range of applications and be amenable to recycling using current adapted techniques.

In order to obtain highly recyclable bio-composites and make them more interesting for industrial use, the ESTELLA project team is created.

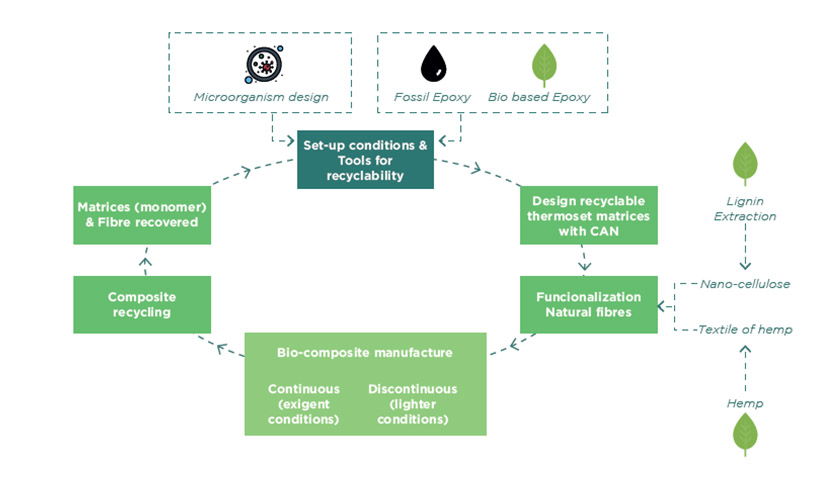

The ESTELLA project brings together European experts capable of addressing the entire value chain, from biomass precursor extraction, the raw material design, manufacturing and recycling processes. This will ensure the production of materials with excellent properties and with the maximum recovery rate of their components, and strengthen the environmental and economic dimension of the thermoset value chain.

For this purpose, ESTELLA will introduce Covalent Adaptive Networks into epoxy resins and functionalized bio-fibres (nano-cellulose and hemp) on the one hand. On the other hand, manufacturing and recycling processes will be adapted to reduce energy consumption and greenhouse emissions.

The ESTELLA methodology is characterized by the definition of different work packages each dedicated to one or more technologies and with specific objectives to enable the development of recyclable thermoset bio-composites. The methodology implemented is based on four main steps:

(a) development of innovative recyclable thermoset matrices

(b) obtaining fibres (continuous and discontinuous) with high compatibility with developed resins

(c) design and manufacture of composites

(d) recycling of matrices and composites